What Is the Difference Between A Blind Bolt and A Blind Rivet?

Blindbolt UK | 2nd November 2020

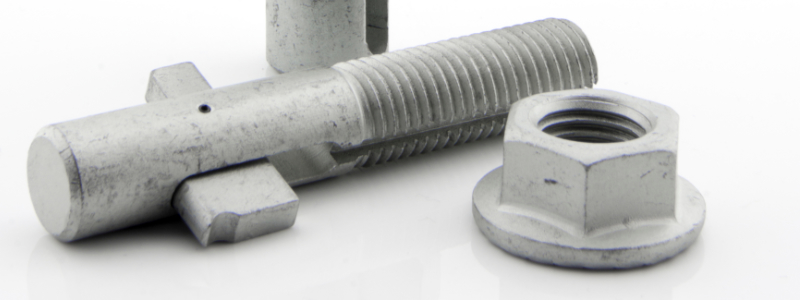

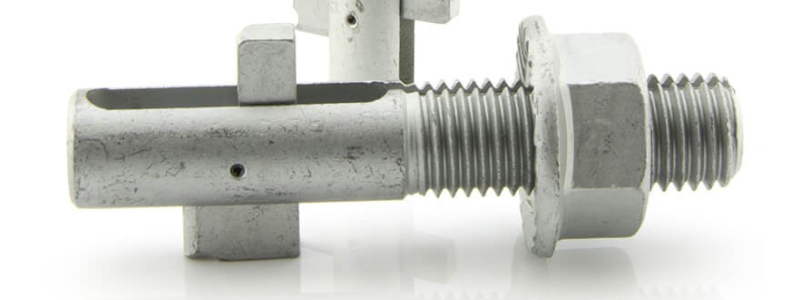

Blind Bolts

Whether your job requires fastening metal on metal or onto other materials like plastic or wood, blind rivets can complete the task securely. Blind rivets have an even higher strength than traditional rivets, so can offer you even more in the way of security when a joint requires extra strength.

Indeed, you can even source blind bolts manufactured from titanium with a shear strength of 90 KSI, making them twice as tough as a standard blind rivet. Both blind rivets and blind bolts can be inserted completely from one side, hence their name. This is in contrast to machine bolts and rivets, for which you need to be able to get at both sides of the material.

How Do I Use A Blind Rivet?

When you look at a blind rivet, you'll see two pieces. The body of the rivet itself, and then within that is a mandrel. When you've established the hole in your two pieces of material, then you can insert the rivet. You'll have a special installation tool which fits the mandrel. Pulling on this 'sets' the rivet by creating a bulge that securely joins the items. The exposed mandrel then breaks off inside the rivet. There are a variety of different metal composites and head shapes to select according to the specifics of your task. Think about the strength and the resistance to corrosion that you need before purchasing.

Combinations of aluminium, steel and stainless steel offer a range of options. As blind rivets are easily installed, resistant to interference and corrosion; installing them can be done without marking the surface of the other materials, they are a popular choice. You can choose an open-ended or close-ended rivet for extra protection against liquids or include a backup washer if you're fastening softer materials. The security of this blind rivet method works well for industrial applications.

If you need it, advice is available on key factors such as grip range, which varies from type to type of blind rivet and may compromise structural integrity if not chosen correctly.

How Do I Use A Blind Bolt?

Blind bolts have many different applications within construction industries. For instance, tasks such as fixing into a boxed section or the cavity of a girder used to be a huge problem - but blind bolts have solved that challenge. Blind bolts provide a high degree of tensile strength and come in different shear strengths to suit the thickness of the materials being fastened. This variation in fixing combinations gives a blind bolt a huge range of possible applications, in addition to an extremely secure fastening.

Blind bolt fasteners will help with the neat and efficient application in many different parts of industry. When speccing up a job, you will want to be sure that you have made the right choice of blind bolts or blind rivets to enable your finished construction to be of superior strength and quality.

Bolted Shut

We can help you to determine whether a blind bolt or a blind rivet is the best choice for the project that you have in mind and are always happy to help advise on any construction. At Blind Bolt, we're continuing to discover brand new avenues where our products can save you time and money. As well as this, we are constantly looking to find new ways to improve our blind fixings in order to provide the highest possible quality of product to our customers.

Interested in finding out more about our blind bolts and how they work? Get in touch with a member of our team today on +61 3 9757 4989 or email us on enquiries@blindbolt.com.au. We look forward to hearing from you.

The Blind Bolt